The global Additive Manufacturing Automation market is undergoing significant transformation, spurred by the increasing demand for faster, more precise, and cost-efficient production methods in various industries, including aerospace, automotive, healthcare, and consumer goods. Additive manufacturing, also known as 3D printing, has evolved from a prototyping tool into a key enabler of automation in the manufacturing process. Automation in additive manufacturing allows for the streamlining of production lines, reduction in human error, and faster turnaround times, thus meeting the evolving demands of industries striving for efficiency and innovation.

The additive manufacturing automation market is projected to grow from USD 4.56 billion in 2023 to USD 12.35 billion by 2028, with a compound annual growth rate (CAGR) of 22.0%. The expansion of Industry 4.0 initiatives, the increasing adoption of smart factories, and advancements in robotics and automation technologies are driving the widespread adoption of automated additive manufacturing solutions. This growth is further fueled by the need for businesses to stay competitive by reducing production costs and increasing customization capabilities.

Get Sample Report of Additive Manufacturing Automation Market @ https://marketintelo.com/request-sample/46097

Market Overview

Additive manufacturing automation involves the integration of automated systems, robotics, and digital technologies with traditional 3D printing processes. These systems include automated material handling, quality control, post-processing, and monitoring capabilities, which enhance the overall production efficiency and ensure consistent product quality. Automation reduces human intervention, improving accuracy and operational speed while allowing manufacturers to scale production and meet specific customization demands.

The benefits of additive manufacturing automation are particularly evident in sectors that require complex, low-volume, high-precision parts. Industries such as aerospace, automotive, and medical device manufacturing rely on 3D printing for rapid prototyping and production, and the ability to automate these processes ensures faster time-to-market and lower manufacturing costs. Furthermore, the rise of personalized and on-demand production is pushing the demand for automated additive manufacturing solutions.

Get Sample Report of Additive Manufacturing Automation Market @ https://marketintelo.com/request-sample/46097

Market Drivers

The additive manufacturing automation market is driven by several key factors:

Increasing Demand for Customization and On-Demand Production

One of the primary drivers of additive manufacturing automation is the growing demand for customized and on-demand production. Traditional manufacturing methods struggle to meet the increasing demand for personalized products, especially in industries like healthcare (e.g., prosthetics and implants) and consumer goods. Additive manufacturing provides a flexible solution that allows for the production of complex, bespoke products without the need for costly molds or tooling. Automating these processes enables manufacturers to efficiently handle low-volume, high-variety production runs, making the process more scalable.

Advances in Robotics and Automation Technologies

Technological advancements in robotics and automation systems are significantly enhancing the capabilities of additive manufacturing. Robots can now handle complex tasks such as material handling, layer deposition, and post-processing with greater precision and speed. Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) algorithms with 3D printers enables real-time process optimization, defect detection, and predictive maintenance. These innovations are revolutionizing the efficiency and productivity of additive manufacturing processes.

Industry 4.0 and Smart Factory Integration

As part of the broader Industry 4.0 revolution, manufacturers are increasingly implementing smart factories that leverage connected devices, automation, and real-time data analysis. Additive manufacturing automation is a crucial component of this transformation, allowing for seamless integration of 3D printing technologies into larger automated production lines. This integration enhances productivity, reduces waste, and facilitates the creation of smart products that can be autonomously monitored and modified during the production process.

Get Sample Report of Additive Manufacturing Automation Market @ https://marketintelo.com/request-sample/46097

Market Segmentation

The additive manufacturing automation market can be segmented based on technology, application, and region.

By Technology

3D Printing and Robotics Integration: This segment includes the use of robotic arms and other automated systems to handle tasks such as loading and unloading parts, maintaining continuous 3D printing operations, and post-processing parts. Robotics integration allows manufacturers to improve speed and consistency in the production process.

AI and Machine Learning for Process Optimization: AI-driven solutions are used for continuous monitoring and optimization of additive manufacturing processes. These systems analyze vast amounts of data from printers and robots to ensure quality control and identify potential issues before they affect production, reducing the need for manual intervention and improving operational efficiency.

Automated Material Handling and Post-Processing: Automated systems are increasingly being employed to manage raw materials and post-processing tasks such as cleaning, curing, and surface finishing. These systems improve efficiency, reduce handling errors, and ensure high-quality end products.

By Application

Aerospace and Defense: The aerospace and defense industry has been one of the early adopters of additive manufacturing due to its ability to produce complex parts with minimal material waste. Automation in additive manufacturing allows for faster production times and the ability to create custom parts for highly specialized applications, such as turbine blades, brackets, and structural components.

Automotive: The automotive industry is utilizing additive manufacturing for rapid prototyping, tooling, and production of customized parts. Automated additive manufacturing systems help manufacturers reduce the time required to develop new vehicle components and enable on-demand production of spare parts.

Healthcare: The healthcare sector benefits from additive manufacturing automation for the production of custom implants, prosthetics, and medical devices. Automation ensures the precision and consistency required for these life-saving devices, and it enables the production of complex, patient-specific solutions at scale.

Consumer Goods: As consumer preferences shift towards personalized products, additive manufacturing automation enables the mass customization of goods such as footwear, eyewear, and electronics. This sector benefits from the flexibility and speed that automated 3D printing provides.

By Region

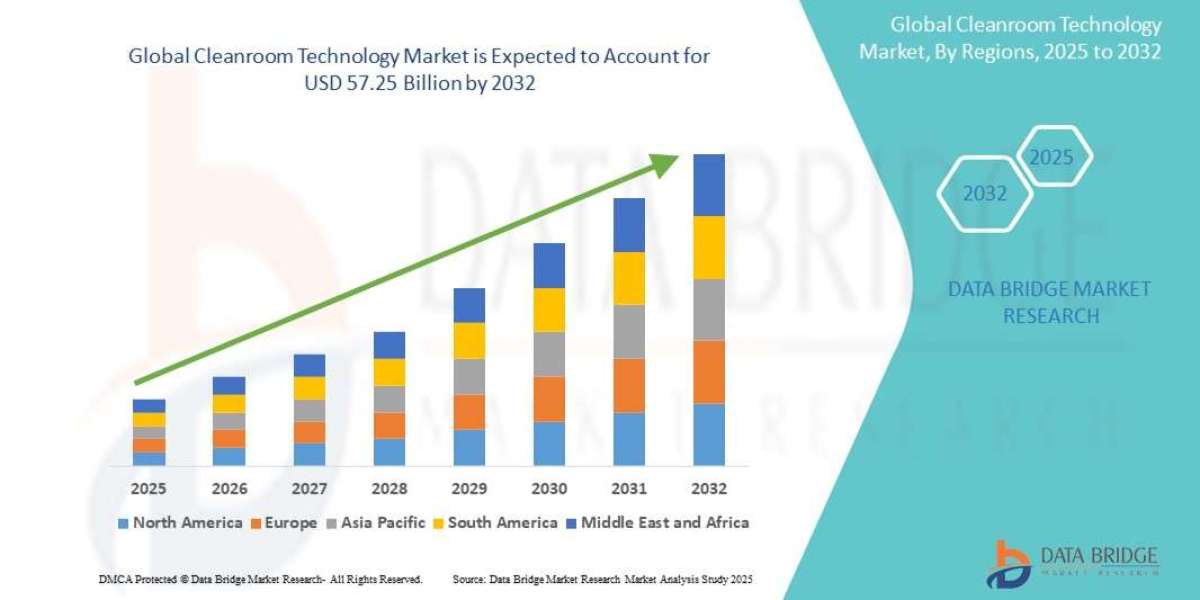

The additive manufacturing automation market is analyzed across key regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America and Europe are expected to remain dominant in the adoption of additive manufacturing automation due to their strong industrial bases and technological advancements. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by the rapid industrialization in countries like China, Japan, and India.

Market Challenges

Despite the promising growth prospects, the additive manufacturing automation market faces a few challenges:

High Initial Investment

The integration of automation technologies into additive manufacturing processes requires significant upfront investment in robotics, AI systems, and specialized 3D printers. While these technologies offer long-term cost savings, the high initial capital expenditure may pose a barrier for small and medium-sized enterprises (SMEs) looking to adopt these solutions.

Complexity of Process Integration

Integrating additive manufacturing automation into existing production lines can be complex, particularly in industries with established manufacturing processes. The transition to automated systems requires careful planning and coordination, as well as training for staff to operate new technologies. Overcoming these challenges is essential for successful adoption.

Material Limitations

While additive manufacturing has made significant strides, there are still limitations in terms of the range of materials that can be used in 3D printing. The automation of additive manufacturing is often constrained by the availability of suitable materials, which can impact production efficiency and the range of applications for which additive manufacturing is viable.

Read Full Research Study: https://marketintelo.com/report/additive-manufacturing-automation-market

Competitive Landscape

The additive manufacturing automation market is highly competitive, with several prominent players offering innovative solutions. Key companies in the market include:

Stratasys Ltd.

3D Systems Corporation

Siemens AG

ABB Ltd.

EOS GmbH

KUKA AG

These companies are investing heavily in R&D to advance automation technologies and expand their product portfolios. Strategic partnerships and acquisitions are common in this market, as companies look to enhance their technological capabilities and strengthen their position in the growing additive manufacturing automation space.

Conclusion

The additive manufacturing automation market is poised for rapid growth, with an expected CAGR of 22.0% and a market size projected to reach USD 12.35 billion by 2028. Driven by advancements in robotics, AI, and Industry 4.0 initiatives, the integration of automation into additive manufacturing processes is revolutionizing industries across the globe. As businesses strive for efficiency, customization, and cost savings, additive manufacturing automation is becoming a critical component of modern industrial production.

Related Report