Your Brother or Babylock machine sits ready. Threads loaded, stabilizer hooped, customer waiting. You have the logo on your screen—a JPG file your client emailed this morning. Twenty minutes later, after wrestling with conversion software, guessing at settings, and running three failed test stitches, you still do not have a PES file that sews correctly. The text blurs. The edges pucker. The colors look nothing like the original artwork. This scenario plays out in embroidery shops and home studios every single day. The frustration is real, but it is also avoidable. Learning to Convert JPG to PES at professional quality levels is the difference between fighting your machine and creating flawless embroidery efficiently, consistently, and profitably.

This guide delivers the exact techniques professional digitizers use to transform ordinary JPG files into exceptional PES embroidery files. You will learn why most conversions fail, how to prepare your artwork for success, which software settings actually matter, and the quality standards that separate amateur output from production-ready results. Whether you run a commercial embroidery business or stitch for passion, these techniques will forever change how you approach PES conversion.

Why JPG to PES Conversion Fails for Most People

Before we discuss solutions, we must confront the problem honestly. The vast majority of JPG to PES conversion attempts fail because users fundamentally misunderstand what they are trying to accomplish.

A JPG shows you what the logo looks like. It captures color and form through thousands or millions of individual pixels. It contains zero information about how to construct that image with thread, needle, and fabric. It does not know what a satin stitch is. It cannot compensate for fabric stretch. It has never heard of underlay.

A PES file tells your machine how to sew. Brother and Babylock machines read this proprietary format. PES files contain stitch coordinates, color change commands, jump instructions, and trim signals. They are not pictures. They are blueprints.

When you attempt to "convert" a JPG to PES, you are not performing a simple file translation. You are asking software to reverse-engineer construction instructions from a finished visual appearance. This is difficult. It requires sophisticated algorithms, extensive user input, and almost always requires manual editing afterward.

The software that promises one-click conversion is lying. It can generate a PES file from your JPG, but it cannot guarantee that file will sew correctly. The difference between a file that sews and a file that sews beautifully is the difference between amateur and professional conversion techniques.

Step 1: Source Image Evaluation and Preparation

Professional PES conversion begins before you open any embroidery software. It begins with honest assessment of your source material.

Resolution is destiny. A JPG exported from professional design software at 300 DPI contains sufficient detail for accurate tracing. A JPG saved from a website at 72 DPI contains one-sixth the information. Your conversion software cannot invent missing detail. It guesses. Guessing produces poor results.

Clarity determines accuracy. Sharp edges, high contrast, and distinct color boundaries convert cleanly. Blurry edges, low contrast, and JPEG compression artifacts force your software to interpret rather than trace. Interpretations rarely match original intent.

Size matters desperately. A logo destined for a 4-inch chest placement requires different handling than the same logo destined for a 2-inch cap placement. Text that reads perfectly at 4 inches becomes illegible mush at 2 inches. Evaluate your target size before conversion, not after.

Color count drives complexity. Every distinct color in your JPG will become a thread change in your PES file. Professional embroidery rarely exceeds eight to ten colors. If your JPG contains gradients, drop shadows, or subtle color variations, you must simplify before conversion.

Preparation protocol:

Open your JPG in photo editing software (Photoshop, GIMP, Affinity Photo, or even Preview).

Crop tightly to remove all background and white space.

Increase contrast aggressively using Levels or Curves. Pure black shapes against pure white backgrounds trace most accurately.

Posterize to reduce colors. Target 3-8 colors maximum for most logo embroidery.

Remove gradients entirely. Convert them to solid color zones.

Save as PNG or TIFF at 300 DPI. JPG recompression introduces artifacts.

This preparation work takes five minutes. It improves your conversion results by an order of magnitude.

Step 2: Choose Your Conversion Path

You have four distinct routes from JPG to PES. Each serves different needs, budgets, and quality expectations.

Path A: Professional Digitizing Service

You send your prepared artwork to a professional embroidery digitizer. They return a production-ready PES file optimized for your specific Brother or Babylock machine and your target fabric.

This path delivers guaranteed commercial quality. Professional digitizers understand Brother's PES format intricacies. They know how much pull compensation your stretch polo requires. They select appropriate underlay for your fabric weight. They test-stitch and revise until you approve.

Cost ranges from $15 to $50 per design. For businesses, this is not an expense. It is the cost of a flawless finished product. For hobbyists with one precious design, it is insurance against wasted thread and ruined garments.

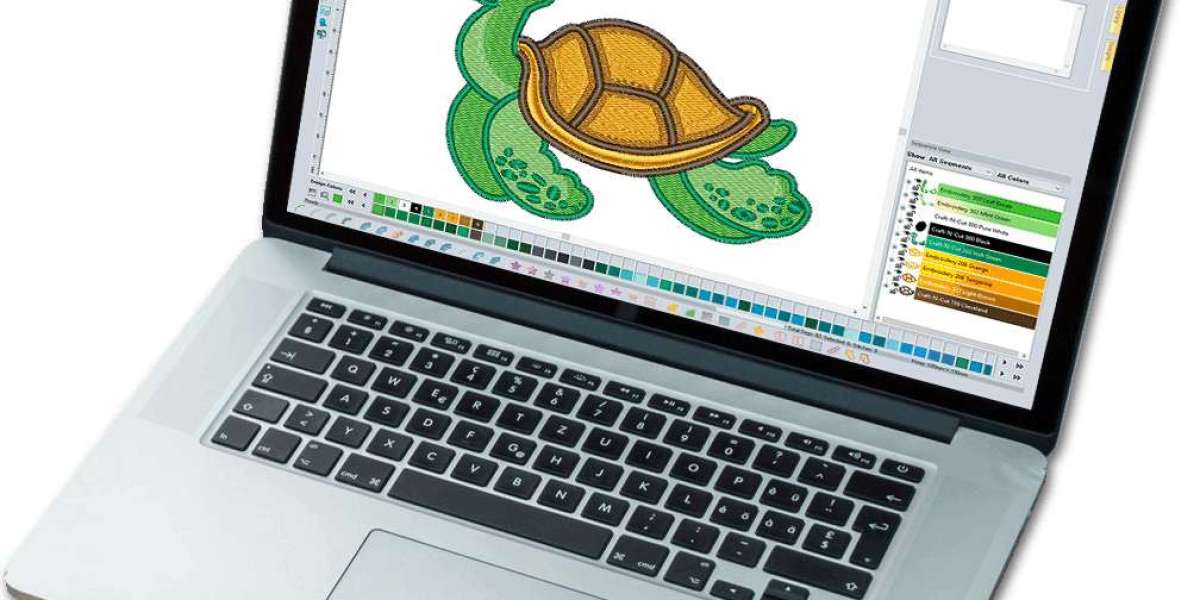

Path B: Professional Digitizing Software

You purchase Brother PE Design, Hatch Embroidery, Embrilliance, Embird, or SewArt and create PES files yourself.

This path offers unlimited creative control and eliminates per-design fees. Software costs range from $85 (SewArt) to $600+ (PE Design, Hatch). The learning curve is substantial. Expect months of practice before producing files comparable to professional digitizers.

Path C: Built-In Auto-Digitizing

You use the auto-digitizing feature included in your embroidery software or machine's design software.

This path is fast and accessible. Modern auto-digitizing algorithms produce acceptable results for simple, high-contrast, low-detail designs. They fail catastrophically on complex logos, small text, and fine details. Results always require manual editing.

Path D: Online Converters

You upload your JPG to a website, click convert, and download a PES file minutes later.

This path is cheap and tempting. It is also consistently disappointing. Online converters are black boxes. You cannot adjust settings. You cannot edit intermediate results. You receive whatever their algorithm produces, which is almost never production-ready.

Our recommendation: For customer logos, branded apparel, gifts, or any project where quality reflects on you, use Path A or invest fully in Path B. Path C works for simple personal projects. Path D is acceptable only for designs you are willing to abandon.

Step 3: Professional Auto-Digitizing Settings

If you use auto-digitizing features in PE Design, Hatch, or Embrilliance, these settings dramatically impact your results.

Design Type: Select "Logo" or "Graphic" rather than "Photo" or "Cross-Stitch." This tells the algorithm to prioritize sharp edges and solid fills over tonal variation.

Stitch Type Preference: Select "Satin" for text and narrow columns. Select "Fill" for large background areas. Some software attempts to auto-detect appropriate stitch types; manual override usually improves results.

Detail Level: Medium to High settings preserve more original detail but also preserve more noise and artifacts. For clean, high-contrast source images, use higher settings. For low-resolution or messy source images, lower settings produce cleaner paths.

Color Reduction: Set your target color count manually. Do not accept the software's default, which often preserves unnecessary color variations. Match your actual logo colors exactly.

Pull Compensation: Default values are conservative. For knit fabrics and stretch materials, increase compensation by 20-30%. For stable wovens, default often suffices.

Underlay: Enable edge underlay for all satin stitch elements. Enable center underlay for all fill areas larger than 1/2 inch. Do not rely on default underlay settings; configure them intentionally.

Export Settings: Save as PES format, version compatible with your machine. Newer Brother machines read PES versions through 11 or higher. Older machines may require PES 5 or 6. Consult your manual.

Step 4: Manual Editing—The Professional Difference

Auto-digitizing creates a starting point. Manual editing creates a professional PES file. These editing techniques separate adequate from exceptional.

Simplify excessive nodes. Auto-tracing generates far more anchor points than necessary. Use your software's path simplification tools to reduce node count while preserving shape accuracy. Cleaner paths stitch smoother, transfer faster, and edit more easily.

Widen thin lines. Hairline rules, delicate serifs, and thin strokes that look acceptable in your JPG will stitch as broken, wobbly threads. Manually thicken any element narrower than 1.5mm at stitch size. Your embroidery will look bolder and more intentional.

Adjust stitch direction. Auto-digitized fills default to 45-degree angles regardless of design contours. Rotate stitch angles to follow the natural flow of your artwork. Letters stitch more cleanly with vertical satins or horizontal fills depending on orientation. Circular elements benefit from radial stitch patterns.

Check density visually. Zoom to actual stitch size in simulation view. Can you see fabric between stitches? Reduce density. Does the fill look overly stiff and dense? Reduce density. Does the fill appear thin and inadequate? Increase density. Trust your eyes, not default values.

Eliminate redundant color changes. Auto-digitizing sometimes assigns separate stitch layers to visually identical colors that arrived from different source areas. Merge them. Fewer color changes mean faster production and lower labor cost.

Overlap adjacent color zones. Adjacent color areas should overlap slightly (0.3-0.5mm) to prevent fabric from peeking through between them. Auto-digitized files often butt edges exactly, creating visible gaps after pull compensation.

Add corner sharpening. Satin stitches naturally round off sharp corners. Use your software's corner tools to add extra stitches, adjust entry and exit points, or split corners to preserve angular geometry.

Step 5: PES-Specific Optimization

PES format has unique characteristics that distinguish it from DST, EXP, or other embroidery formats.

Color palette storage: Unlike DST, PES files can store actual thread color information, not just position numbers. When you assign thread colors in your software, this data embeds in the PES file. Brother machines display these colors on screen, helping operators verify correct thread loads. Take advantage of this feature. Maintain a standardized thread brand and assign colors consistently.

Resizing behavior: PES files contain stitch data for specific dimensions. Scaling a PES file up or down in your machine distorts stitch density. Always digitize at or near your target stitch size. Do not rely on machine scaling for production work.

Design limits: PES format supports up to 500,000 stitches and 128 color changes. Practical limits are lower. Extremely dense, high-stitch-count designs may strain machine memory and slow processing. Optimize for efficiency, not maximum stitch count.

Backward compatibility: Newer PES versions include features older machines cannot interpret. If you distribute files to customers or other shops, save a backward-compatible version. PES 5 or 6 works on virtually all Brother and Babylock machines manufactured since 2000.

Step 6: Fabric-Specific Parameter Adjustment

Your PES file is not complete until you have adjusted parameters for your specific fabric. This is the step most hobbyists skip and professionals never skip.

Woven cotton/polyester: Stable, predictable. Standard underlay. Moderate pull compensation (0.3-0.5mm). Medium density. Default settings often work well.

Knit pique/jersey: Stretchy. Increase pull compensation significantly, especially horizontally (0.6-1.0mm). Add aggressive underlay. Reduce density 10-20% to maintain fabric drape.

Performance mesh/athletic knit: Highly stretchable. Maximum pull compensation. Dense underlay essential. Consider reducing top stitch density further. Test stitch on actual fabric before production.

Cap backs: Structured, curved. Special cap digitizing techniques required. Design proportions must adjust for visual correction on curved surface. Pull compensation differs from flat embroidery. Underlay essential but must not create excessive bulk.

Towels/terry: Napped surface. Water-soluble topping required. Reduce density. Underlay designed to anchor stitches without disappearing into nap. Avoid small text and fine details.

Denim/heavy twill: Stable, thick. Standard underlay. Moderate pull compensation. Density may increase slightly for better coverage on dark fabric.

Leather/vinyl: Non-forgiving. No underlay (permanent needle holes). Reduce density significantly. No pull compensation. Test stitch mandatory.

Your PES file must match your fabric. There is no universal setting that works across all materials. Professional digitizers ask about fabric before they create your file. If your software does not ask, you must adjust manually.

Step 7: Test Stitch Protocol

No PES file ships from professional digitizers without physical test stitching. You should adopt the same discipline.

Hoop production-equivalent fabric. Test on the exact fabric you will use for final production. A file that stitches beautifully on stiff twill may pucker catastrophically on stretch pique.

Use production stabilizer. Same brand, same weight, same application method. Test conditions must match production conditions exactly.

Run at production speed. Do not slow your machine for testing. You need to know how the file performs at actual operating speeds.

Examine critically. Check text legibility. Verify circle and square shapes are not distorted. Look for gaps between color layers. Assess the back for excessive thread buildup or tension issues. Run your finger across the surface. Smooth or bumpy?

Measure against artwork. Place your test stitch-out next to the original JPG or customer approval art. Does it capture the essential character of the logo? Does it meet your quality standards?

Revise and retest. Expect to iterate. Professional digitizers rarely achieve perfection on first attempt. The difference is not avoiding mistakes; it is catching them before the customer does.

Step 8: Building Your PES Asset Library

Your approved PES file is now a valuable production asset with ongoing utility.

Store with documentation. Maintain digital folders for each customer containing their approved PES file, native editable file (EMB, VIP, etc.), test stitch-out photo, thread color mapping, and any special instructions. When that customer reorders six months later, you have everything you need.

Maintain version control. Logo updated? Customer requested different size? Keep master files clearly labeled. COMPANY_LOGO_2023_4IN.PES and COMPANY_LOGO_2024_4IN.PES prevent stitching wrong version.

Document thread assignments. PES files store color information, but different software and different machines interpret this data inconsistently. Maintain your own documentation: Color 1 = Madeira Red 1004, Color 2 = Madeira Black 1000, etc.

Backup religiously. PES files are small but irreplaceable. Local backup, cloud backup, off-site backup. Losing a master PES file forces expensive redigitizing.

Step 9: When to Convert, When to Outsource

The most successful embroidery businesses do not convert every JPG themselves. They strategically choose when to invest internal time and when to pay external experts.

Convert internally when:

Designs are simple with few colors and minimal detail

You are prototyping and iterating rapidly

You have invested in software and training

Your production volume justifies the learning curve

Outsource professionally when:

Customer logos require perfect brand reproduction

Designs include small text or fine details

Fabric is challenging (stretch, nap, sheer)

Production runs exceed twenty-five pieces

Your internal conversions consistently underperform

The hybrid approach: Maintain basic conversion capability for simple edits and small jobs. Outsource complex logos and high-volume projects to specialized digitizing services. This balances cost control with quality assurance.

Conclusion: From Frustration to Mastery

Converting JPG to PES at professional quality levels is not magic. It is not luck. It is deliberate, repeatable technique applied consistently across every design.

Start with honest source image evaluation. Prepare your artwork deliberately. Choose the appropriate conversion path for your needs and budget. Configure auto-digitizing settings intentionally. Edit manually with professional techniques. Optimize for your specific fabric. Test stitch without exception. Document and protect your approved files.

The gap between a PES file that runs and a PES file that runs beautifully is the gap between default settings and intentional configuration. It is the gap between accepting auto-digitized output and manually refining paths, angles, and densities. It is the gap between hoping for the best and testing until perfection.

Your Brother or Babylock machine is capable of stunning embroidery. It wants to produce clean edges, sharp details, and vibrant colors. It is waiting for instructions that respect its capabilities and compensate for its limitations. Those instructions come from you—through the PES files you create or commission.

Every time you convert JPG to PES with professional techniques, you honor your customer's brand, protect your reputation, and demonstrate mastery of your craft. That is worth the extra five minutes of preparation. That is worth the investment in proper tools. That is worth the discipline of test stitching and revision.

The machine is ready. Your thread is loaded. Your fabric is hooped. Now you have the knowledge to create PES files that deliver the results your customers expect and your reputation demands. Go stitch something beautiful.