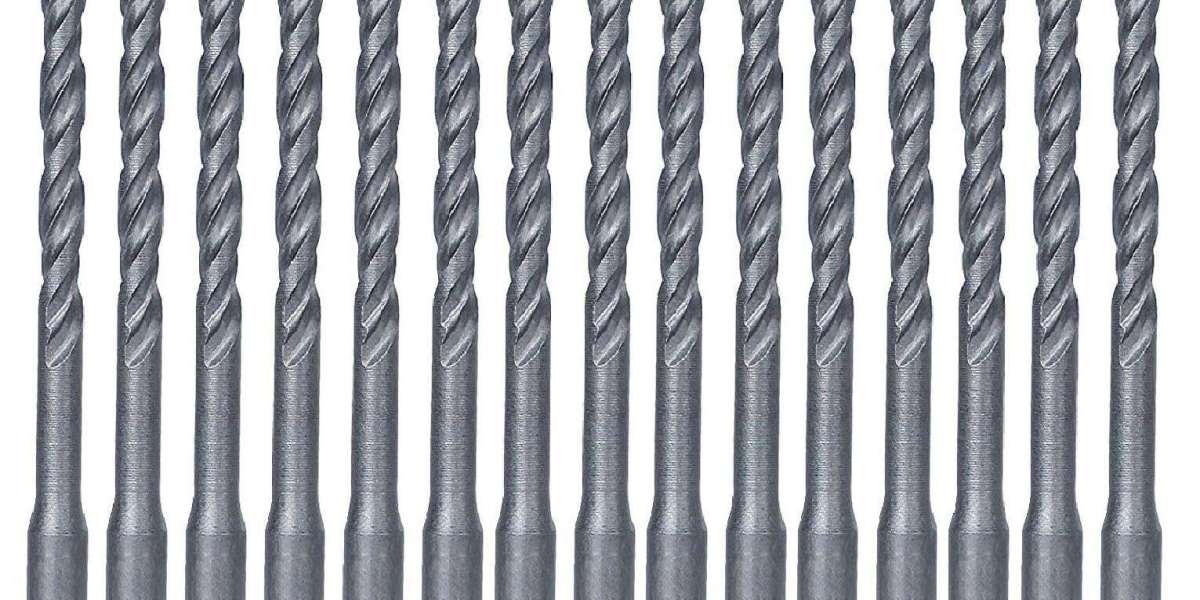

In modern construction and renovation work, the Fangda Hammer Drill Bit from the brand fangda-tools functions as a bridge between raw structural material and human intention, translating rotational motion and percussive energy into clean, purposeful cavities within brick, block, and concrete. It is less a blunt instrument than a coordinated system that synchronizes speed, impact, and stability to produce consistent results in demanding environments.

Effective masonry drilling depends on the careful interaction between impact force and cutting geometry. Each strike fractures microscopic portions of the material while rotation clears debris from the cutting zone. When these two actions are balanced, resistance becomes predictable, allowing the operator to maintain steady pressure without fighting the tool. The rhythm that emerges often feels closer to guided progress than brute penetration.

Tip design plays a central role in how energy is transmitted into the substrate. Angles, edge profiles, and surface treatment influence how efficiently force is concentrated at the point of contact. A thoughtfully shaped tip reduces skidding on hard surfaces and encourages immediate engagement, which is particularly important when starting holes on uneven or glazed masonry.

Flute geometry is equally critical. Well-considered channels carry dust and fragments away from the cutting face, preventing clogging and reducing friction. This continuous evacuation of waste keeps the drilling path open and minimizes the need for frequent withdrawal, supporting a smoother workflow across multiple holes.

The relationship between bit and machine cannot be overlooked. Chuck compatibility, shank fit, and overall balance determine how accurately impact energy is delivered. When these elements align, vibration is moderated and the operator gains greater control, making it easier to maintain alignment even during deeper passes.

Technique remains a decisive factor in outcomes. Consistent pressure, proper body positioning, and an awareness of material density all shape the final result. Experienced users often allow the tool to work at its own pace rather than forcing rapid advancement, recognizing that patience can produce cleaner, more accurate holes.

Site conditions introduce additional variables. Temperature, dust levels, and the presence of embedded aggregates can alter how masonry responds to drilling. Adapting feed rate and angle to these changing conditions reflects a professional approach that prioritizes precision over haste.

From a broader perspective, reliable drilling tools contribute to safer, more efficient construction practices. Cleanly formed holes simplify anchor installation, conduit placement, and fixture mounting, reducing rework and material waste. Over time, this supports a more disciplined and sustainable building process.

Collaboration between tool designers and field professionals continually refines performance. Feedback from real job sites informs incremental improvements in durability, handling, and compatibility with a wide range of hammer drills. This iterative dialogue ensures that new products evolve in response to practical needs rather than abstract specifications.

Ultimately, drilling is not merely a technical step but part of a larger craft that connects planning, execution, and finish quality. When tools, machines, and human judgment operate in concert, the result is work that feels deliberate, controlled, and structurally sound.

If your next wall is waiting for its opening, let your curiosity take the first pass at https://www.fangda-tools.com/ and see where your projects travel next.